- The Ligtex™ material shows superior performance as “Roll = Roll Lining Material” for Pickling Line.

- Originally, “reinforced phenol material with cotton substrate” and “FRP material (glass-fiber-based reinforced polyester resin or epoxy resin material)” had been widely used as roll lining material for Pickling Line. However, the chemical resistance of those materials is not high enough to have the roll survive in high concentrated acid bath and new material with extended service life had been highly expected.

- The exclusively developed “Ligtex™ LG-5310” has been used continuously at main steel making plants in Japan right after our success in its development in 2002. Rolls with lining of “Ligtex™ LG-5310” are applied to the coil pickling lines in various hot rolling mill plants, and their service life extended by several times more compared to rolls with conventional material. Long lifetime was achieved from our company motivation focusing below properties.

High Bonding Strength Between “Substrate Material and Resin” in Compound

The bonding strength between “substrate and resin” in Ligtex™ material is superior compared to that of “resin and fiber” in phenol compound or “resin and glass fiber” in conventional FRP. Familiarity of “substrate and resin“ of Ligtex™ brings excellent bonding strength.

Superior Chemical Resistance

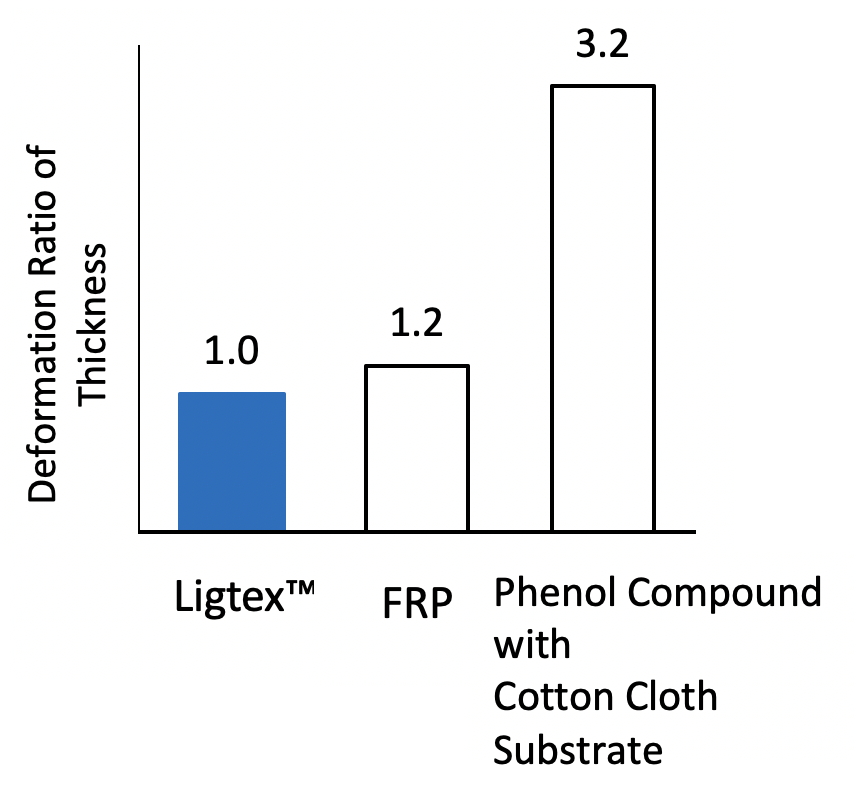

The swelling variation measurement was carried out with 40mm square x 5mm thickness of each material below under 10% hydrochloric acid in 85℃ for 48 hours. “Ligtex™” material shows much lower dimensional change in thickness than “FRP” or “Phenol Compound Material”. This result indicates that declining of bonding strength in “Ligtex™” material is the most preventative against aggressiveness of acid in high temperature.

Resistance Against Loading Attack on the Roll Surface

It is said that the roll surface is continuously changing its shape during the transportation of flat sheet due to the nip pressure, which means lining material gets deformed when there is load. And it gets back elastically when load is removed. Thanks to familiarity of substrate fiber to resin, Ligtex™ can withstand repeatable load better.

It has great flexibility compared to glass-fiber compound, that the load per area is smaller due to its wider nip width.

High Resistance against Abrasive Weariness

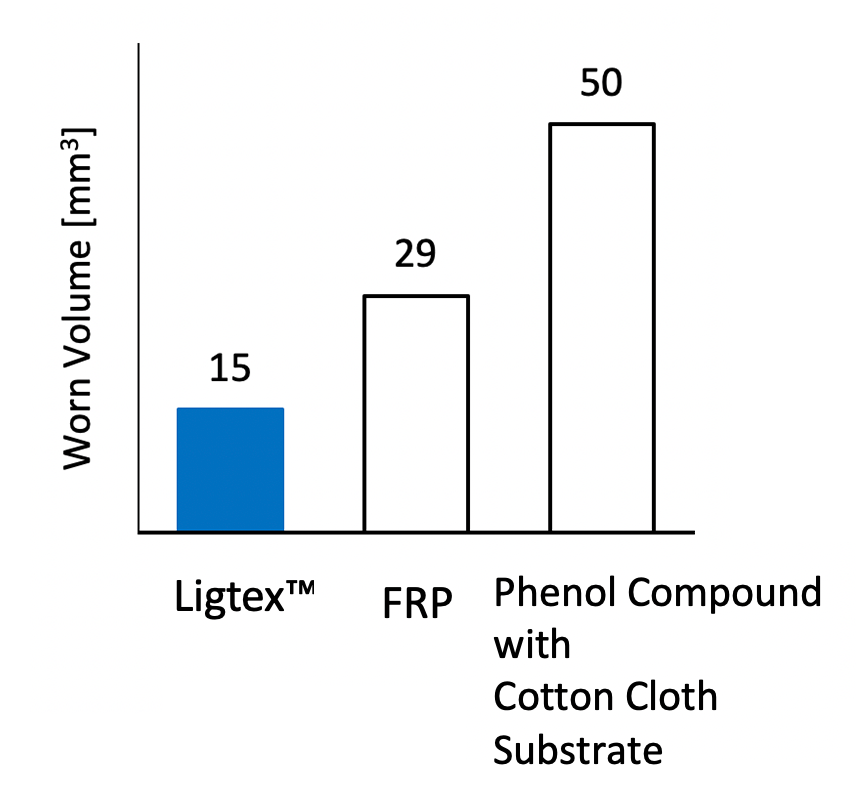

In order to evaluate the resistance against abrasive weariness, Taber Type Abrasion Test was carried out.(CS-10, 1000cycle) Comparison with other materials are shown below.